Analysis, customisation, prototyping and assembly for industrial automation applications

The selection and development of integrated solutions for industrial automation is one of the activities on which Digimax is particularly appreciated within the national market and on which particular energy and resources have been concentrated.

Digimax's specialised team analyses the objectives and requirements of industrial applications in a customised manner, identifying and developing the best industrial and IoT solutions. Knowledge of industrial markets combined with experience and know-how enable Digimax to translate customer needs into operational business models.

Collaboration with the world's most innovative manufacturers also enables the development of cutting-edge solutions using the latest standards, protocols and infrastructure.

Each project is studied and implemented in synergy with our partners, Product Managers and Field Application Engineers.

Our only goal? To provide a turnkey solution with a set of tried and tested products for the specific application required, while at the same time accompanying the client partner in the consultation of kits and integrated products that can add value to their project.

PROTOTYPING

![]()

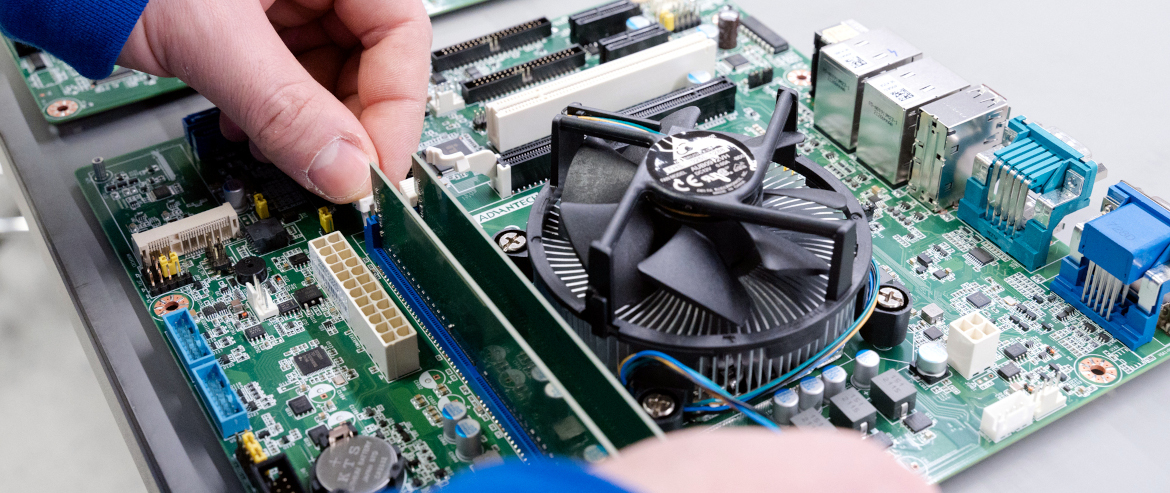

ASSEMBLING

![]()

BURN-IN TESTING

![]()

AFTER-SALES

![]()

What are the activities and services offered by Digimax?

Study and prototyping of the industrial application

Analysis of the industrial application and selection of the most suitable technology

We analyse the needs of the project and propose the best hardware and software platforms to the customer, providing the best technology choice for the application in question.

I/O interfaces and customised connections

Serial ports, LAN, USB and any other interface can be added or customised on all our embedded systems, improving flexibility and scalability

Add-on Boards

We test and integrate the compatibility of add-on cards (customer-owned or third-party) on PCI, PCI-ex slots, ensuring adaptability with Linux, Microsoft Professional or Embedded OSes.

Customised cabling

Custom cables for LVDS display and LED backlight connections and any other cables for interfacing PC peripherals, such as USB cables, Ethernet cables and power supply cables.

Customised BIOS

We can customise the BIOS of our industrial motherboards with the customer's logo and special functions or default settings. We also create setting configurations to enable the embedded board or industrial PC to maintain these settings even if the CMOS battery loses its charge. Other analysis tasks can of course be managed and developed according to the specific needs of our customers.

Assembly, production and testing

Certified professional assembly

We assemble all our products in Italy, in the XLAB technical laboratory with ISO9001 quality certification.

Embedded operating systems

We build and install Microsoft IoT embedded operating systems tailored to the industrial application. Each initial installation will be saved and archived with the functionality required by the customer in order to replicate the same installation on mass production machines.

Testing and test reports

For each computer or industrial board assembled by us, we produce a list of workmanship and test reports using Burn-In software. Each report is supplied with each computer to certify each individual function.

Logistics Services

Labelling and packaging

We can take care of ad hoc packaging with customised labels and ribbons.

Stock management

We offer advanced logistics services for stock optimisation with planning of scheduled orders and recall orders with very fast material delivery.

BOM management

For our assembled industrial computers, we can all trace the list of inserted components, which can be attached to the acceptance tests at the end of product traceability.

After-sales support

Garanzia globale ed estesa

We can offer extended warranties of up to 5 years on our product range, giving you peace of mind throughout your project.

RMA service

We have an RMA area for fast repairs and technical support. Second level support can always be offered directly through the manufacturer.

Technical telephone support

A team of technicians available for full telephone technical support throughout the project lifecycle

EOL and PCN management

We offer proactive end-of-life management of hardware we sell (EOL) and product change notifications (PCN) for all components included in the project.

Industry 4.0 and IoT

When it comes to Industry 4.0 and IoT DIGIMAX is at the forefront in the design of a wide range of solutions suitable for smart factories.

The group is at the customer's service for the consultancy of every project related to technological innovation and Industry 4.0, and for the study of integrations or customisation of numerous IoT hardware products and systems.

In combination with hardware systems, DIGIMAX offers a complete and customised package with the most innovative software solutions and best suited to the applications required: from software integrations with cloud systems to the creation of dashboards for man-machine interfaces, developed for use on computers or mobile phones.