What factors affect the reliability of the power supply unit

Published : 08/03/2022 10:00:00

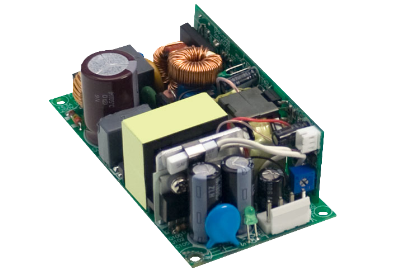

Industrial power supplies allow the operation of a wide range of electronic equipment such as conveyor belts, photovoltaic networks, machine tools, industrial tools, electric vehicles, charging stations and more. The systems and equipment in which they are used are often subject to the negative effects of adverse weather conditions, temperature ranges, humidity and pressure conditions that compromise their operation.

The reliability of the power supply is essential to ensure that the equipment to which it is associated is powered in all circumstances, regardless of the conditions of use; the consequences of any power outages can in fact affect not only the performance of a production line but also on safety systems or monitoring equipment in real time and medical instruments.

For these reasons it is necessary to study with precision the factors that most influence the reliability of power supplies , developing them directly in the analysis and design phase. Below we have collected an overview to summarize the main factors to consider to keep power supply solutions reliable over time .

What are the main factors affecting the reliability of industrial power supplies?

The complexity of the power module

More complex electrical circuit designs often incorporate more electrical components that add to the sophistication of the power module. In other words, the more complex the design, the greater the chance of encountering malfunctioning components or problems with their integration into the power module.

Thermal, mechanical and electrical stress

Within power circuits, stress can be declined and classified into three main types: thermal, mechanical and electrical.

Thermal Stress

Thermal stress is considered to be the most challenging and insidious type of stress, as it manifests itself in several ways. The higher temperatures inside the enclosure are often linked to the natural tendency of power supplies to dissipate heat . Most of the power supplied by the power supply to electronic equipment ends up as dissipated heat which remains enclosed in the electrical circuit. This results in a higher overall thermal load inside the power supply.

Mechanical Stress

Mechanical stress on a power supply is related to how and where it is installed and used. This type of stress can cause intermittent failures but also situations of high severity and lasting over time: among the main ones we include the development of dents or cracks in the protection case, the disconnection of components inside the circuits or any disconnections.

Electric Stress

Electrical stress occurs when a component operates beyond its rated value , due to incorrect setup or occasional events that we are not in control of. The effects of electrical stress can for example occur when a capacitor evaluated at a certain voltage sees a voltage spike above the indicated voltage threshold. Premature aging and failure fall into this case.

Overcurrent

An overcurrent condition occurs when current exceeds the rated amperage capacity of a circuit or connected equipment. This phenomenon can affect the reliability of a power supply by reducing its load.

Power surges

Power supplies tend to be affected by voltage swings that take many forms, including voltage interruptions, voltage fluctuations , and more generally voltage dip / rise. These forms of voltage instability can have detrimental effects on operating costs and power reliability.

What are the factors to consider when optimizing industrial power supplies?

The reliability of the power supply can directly affect the performance and life of the electronic equipment to which it is connected and it is for this reason that electrical engineers should anticipate any power anomalies in the design phase. While power supply reliability is affected by a number of factors, the consequences of power outages can be limited by optimizing power requirements and selecting the right components.

Another general recommendation for optimizing the reliability of the power supply modules therefore includes the use of components with certain rated specifications and higher than the values required by the entire system. For example, a component rated for operation at a certain temperature will have significantly improved efficiency when used at a lower temperature range.

In addition to considering the derating factor , electrical engineers should also design power circuits to minimize temperature rise. This requires carefully planned thermal management through reliable airflow and a cooling mode within the power supply.

A good industrial power supply therefore requires adequate design, analysis, components and installation . Rigorous testing is another key factor that plays a vital role in ensuring and authenticating the exact reliability of a power supply.

Digimax is an official partner of recognized manufacturers and provides highly reliable power solutions that can withstand voltage fluctuations, adverse weather conditions, large temperature variations for outdoor applications and more.

INDUSTRIAL POWER MODULES WITH DIGIMAX

-

HRP series Mean Well power supplies with 200% higher peak power

Leggi tutto

Published : 03/30/2022 10:00:00 -

What is CAN-bus protocol and what are its advantages?

Leggi tutto

Published : 07/19/2022 09:30:00 -

Smart chargers for industrial use in 450W, 750W, 1200W and 1700W formats

Leggi tutto

Published : 02/08/2022 09:00:00